FertiLup

- Colombia

- Not registered as any organization

Our project aims to tackle two sets of challenges:

#1- Agricultural sector:

Cultivated croplands and other agricultural activities contribute 14% of the total greenhouse gas (GHG) emissions in Colombia. This accounts for about 2.6MT of CO2 eq generated annually by the crop nutrition sector in Colombia. A significant contributor to these GHG emissions is nitrogen, extensively used in commercial NPK (nitrogen, potassium, and phosphorus) fertilizers. Nitrogen fertilizers produce substantial amounts of nitrous oxide, a greenhouse gas that is 265 times more potent than carbon dioxide.

Colombia consumes over 2 million tons of fertilizers annually, with the inorganic fertilizer market, comprising over 95% of total sales. Furthermore, fertilizer prices in Colombia are 30-50% higher than global fertilizer prices since approximately 70% of its fertilizer consumption is imported from Europe and other regions. As a result, Colombia, like many countries in the world, faces economic challenges in sustaining its agricultural practices while mitigating environmental impact.

Silicon is crucial in agriculture, enhancing soil quality, crop yield, and plant resilience to environmental stresses, pests, and diseases. However, intensive crop cultivation depletes soil silicon levels, contributing to declining yields. Subtropical and tropical soils, in particular, are often low in available silicon and could benefit from silicon fertilization.

#2- Glass waste:

According to data from the World Bank, approximately 9.4 million tonnes of municipal glass waste is generated annually in Latin America and the Caribbean. Globally, achieving high recycling rates for glass is challenging due to the quality of collected waste and high transportation and processing costs. The recycled content in new containers varies based on product specifications and quality standards. Due to these factors, glass bottle manufacturers cannot feasibly use 100% recycled glass (cullet) in new container production; some virgin raw materials are necessary for precise colour control. As much as 30% of glass waste leaving material recovery facilities cannot be processed due to size, type or color constraints.

In Colombia, limited recycling infrastructure results in glass waste being landfilled, stockpiled in low-income communities or transported very long distances. Glass is heavy, leading to increased GHG emissions during transportation. This is a significant concern as products undergo numerous stages of transport throughout their life cycles. In addition, more glass packaging is imported into the country compared to domestic production which means that there will always be a surplus of glass waste in the system.

In 2018, 43,500 tonnes of glass waste was landfilled in Cartagena alone (representing 9% of the total waste). Additionally, Colombia has approximately 147 landfills, with many nearing full capacity. The supply chain logistics of bottle manufacturing and the absence of additional high-value markets mean waste collectors (recicladores) struggle to find consistent buyers or equitable prices for collected glass. In just two cities- Cartagena and Bogotá, there are an estimated +1,800 and +4,000 recicladores.

Sources:

Our solution is transforming glass waste which would otherwise end up in landfills, into a soil conditioner/plant nutrient for the crop nutrition sector in Colombia. Glass is composed of three main materials—sand (silicon dioxide), limestone (calcium carbonate), and sodium carbonate. When hydrated, glass silicon produces calcium silicate hydrate, a compound that releases a highly soluble Plant Available Silicon. Silicon is an important plant nutrient and silicon derived from glass converts to a more soluble form for the plant's root structure compared to other sources.

Slag silicates (magnesium and calcium silicates) are commonly used in agriculture in Colombia. However, they offer a very low bioavailable silicon content, typically ranging from 1,000 ppm to 2,000 ppm. In contrast, glass silicon contains more than seven times this concentration. Moreover, slags typically contain high levels of heavy metals that may accumulate in soils.

Maxsil, a contributor to the solution, has patents for a process to transform glass waste into silicon powder and granules. This IP can be leveraged to develop the process so that it is commercially viable and beneficial for the crop nutrition sector in Colombia. The product was designed to be a slow release, and generally only one application is required during a crop cycle. The product can be integrated into irrigation systems, applied to the root system at planting or as a top layer at the time of plant emergence. MaxSil™ (glass silicon) is compatible with organic agriculture and there are no known compatibility issues with common granular or liquid fertilizers.

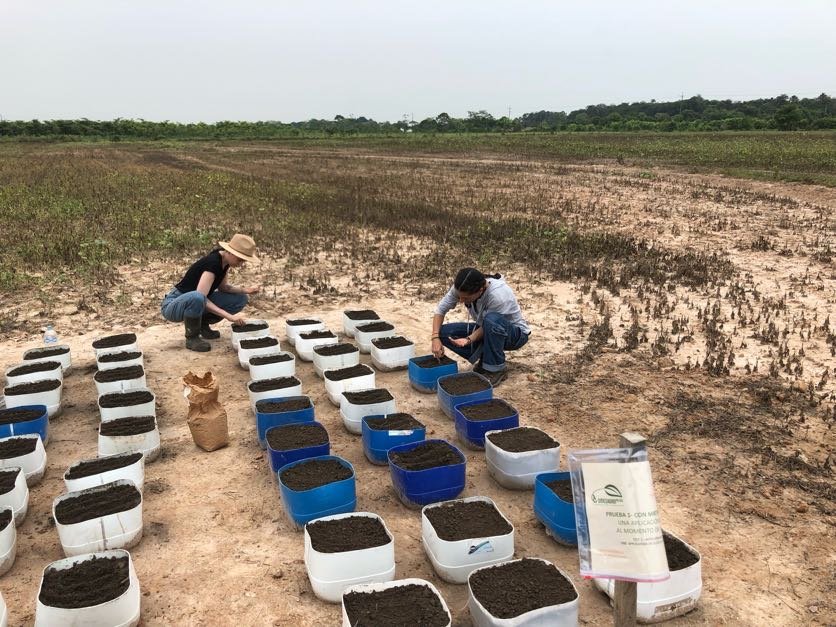

We developed a field trial strategy to assess optimal dosages, impacts on soil quality, and application methods for key Colombian crops with glass silicon. This included evaluating its effect on crop yield, soil quality (pre and post-treatment) at different dosages, impacts to post harvest quality and shelf life, reduction in nitrogen-based fertilizer usage, the effects with compost and potential cost savings for farmers (reduction in nitrogen fertilizer and pesticides). The trials are ongoing, but the results to date have been very promising (further details available in subsequent sections).

Our aim is to establish a recycling-based manufacturing plant in Colombia for producing a glass silicon product, benefiting local farmers and agribusinesses. By processing mixed-color glass, we create a high-value, low-carbon product, providing a reliable market for recycled glass. Initial research suggests that the Caribbean Coast is an ideal location due to limited recycling infrastructure and demand from recicladores. Our strategy involves implementing operations to serve a specific radius for glass waste collection and end customers, thereby aiding Colombia's transition to a circular economy. Our calculations indicate that recycling 1 tonne of glass waste into glass silicon product saves approximately 1.11 tonnes of CO2eq. In addition, our trials have demonstrated a clear synergy between glass silicon and organic matter (compost). Hence, collaborating with composting facilities to enhance the crop nutrition benefits of glass silicon presents another avenue for mitigating GHG emissions in the agricultural sector.

Photo 1- Applying glass silicon product for rice crops

Photo 2- Pre-harvest for rice crops Aug. 2023

FertiLup will benefit Colombian farmers, agribusinesses, waste collectors (recicladores), and the community/residents by providing another reliable market for glass waste collection and a sustainable locally produced soil conditioner/plant nutrient.

We are targeting farmers and agribusinesses in Colombia as we aim to keep product distribution local. Fertilizers represent 12-35% of the agricultural production costs in Colombia. We’ll be collaborating with farming cooperatives and federations to offer sustainable and cost-effective products for cultivators. Farmers will have access to more price stable soil conditioners/plant nutrients that will lessen their reliance on NPK fertilizers, pesticides and lower-quality silicon products (such as slag silicates). Given the supply chain challenges outlined in Q#1, there is an increased urgency to develop initiatives that bolster local food security, economic resilience, and environmental protection.

We conducted interviews with farmers, agronomists and crop federations so that we could better understand the pain points for the agricultural sector in Colombia. We also identified an estimate for the selling prices for the glass silicon and its potential impacts on key crops in Colombia. With a typical dose rate between 30 to 100kg/ha/ crop cycle (depending on crop) and assuming a conservative 10% crop yield increase based on studies, we determined that the gain for farmers could be: +$512USD/ha for rice, +$150 USD/ha for cacao, +$306 USD/ha for coffee and +$162 USD/ha for palm oil.

Our solution will also benefit the informal and formal waste collectors who earn income from the sale of waste materials and have no consistent buyers for glass waste. There needs to be additional profitable solutions (high value end-markets) like what we are proposing to be able to complement the market and purchase the glass waste at a consistently fair price. In the future, we can partner with local governments and brands/producers to improve the glass recycling system.

The United States EPA estimates that every 10,000 tonnes of waste managed per year by recycling-based manufacturing creates 25 direct jobs and up to 100 indirect jobs. As well, there is a low entry barrier to the recycling industry allowing for easier job access and a greater potential for upward mobility. Our adaptable business model enables scalability and replication, providing resilience by allowing us to adjust processing capacity and output to match local supply and demand.

Caitlin is passionate about advancing the circular economy. In 2017, she moved to Cartagena, Colombia, to assist a hotel with waste management and recycling initiatives. Subsequently, she co-founded a foundation on an island near Cartagena, focusing on enhancing waste diversion practices within the hospitality sector. With a drive to implement market and community-driven approaches for glass waste recycling, she co-founded Lup Colombia (Lup). Lup focused on developing low-carbon solutions that could support municipalities and industries.

While based in Cartagena, the team conducted interviews with waste collectors (recicladores) and NGOs, visited waste collection centers (centros de acopios), landfills and met with government entities and other stakeholders in the cities of Bogotá, Cartagena, and Medellin. The financial projections and project design were shaped by these discussions and the practical challenges of the existing system, including factors such as the optimal price point for recicladores to collect glass waste and the preference for selling non-colour separated glass (our solution can process mixed glass). We also considered the actual cost of living for the region, not just the minimum wage, when determining salaries for the manufacturing plant.

After defining the recycling system parameters, we conducted market and technical research to explore technologies and feasible end-markets for recycled glass in Colombia. We explored various options, including its incorporation into construction materials like cement.

We also conducted interviews with farmers and agricultural federations to understand their challenges. Ultimately, it was concluded that producing glass-based soil conditioner/plant nutrient would offer the highest level of economic, social, and environmental sustainability for both the agricultural sector and the recycling system.

Jaime Soriano and Alex Martinez are Colombian agronomists at Didesagro, an agricultural research and technical development organization registered with the ICA-Instituto Colombiano Agropecuario (Colombian Agricultural Institute). Didesagro has extensive experience in crop nutrition, product trials and registration. Alex and Jaime managed the design and execution of the field trials, actively collaborating with farmers and technicians to collect feedback and ensure that the product benefits align with their requirements, without complicating their current agricultural practices.

Maxsil Ltd in Australia has developed the Maxsil™ products, which rank among the top four silicon plant/soil nutrient products globally when comparing Plant Available Silicon levels of competing products, making it a highly cost-effective option. The product is entirely amorphous, eliminating any OH&S concerns, and contains minimal traces of heavy metals. Additionally, it has obtained approval as an Organic Input from the National Association for Sustainable Agriculture Australia organization.

This solution has been developed collaboratively, taking into account the needs of all stakeholders across the value chain.

- Enable a low-carbon and nutritious global food system, across large and small-scale producers plus supply chains that reduce food loss.

- 2. Zero Hunger

- 8. Decent Work and Economic Growth

- 9. Industry, Innovation, and Infrastructure

- 10. Reduced Inequalities

- 12. Responsible Consumption and Production

- 13. Climate Action

- 15. Life on Land

- 17. Partnerships for the Goals

- Prototype

Maxsil built a manufacturing plant in Brisbane, Australia and is already producing a glass silicon product (MaxSil™). The MaxSil™ powder product is being used in field trials in Colombia.

We were selected by a Colombian Program "Moving Colombia's low-carbon development strategy into action" led by the NGO Fondo Acción. Fondo Acción works closely with the Ministry of Environment and various other governmental and non-governmental organizations. The goal of the program was to formulate the project to make it investment ready, using the ‘Logical framework approach’. This included developing a detailed business plan, stakeholder analysis, clients and beneficiaries, legal context and considerations, communication strategy and a Mitigation, Reporting & Verification (MRV)- GHG mitigation calculation. This is a living document, serving as a foundational resource for our ongoing work.

Prior to manufacturing or even selling agricultural products in Colombia, field trials that follow specific protocols are required by the Instituto Colombiano Agropecuario (Colombian Agricultural Institute). We initiated fundraising efforts and secured a grant to carry out multi-crop field trials in 2023 and 2024. Maxsil has extensive field trial studies in different climates including temperate and tropical and for a diverse range of crops. FertiLup’s trials leveraged these results but were designed to align with the agricultural practices, soil conditions and feedback from local technicians/farmers in Colombia.

In 2023, field trials were carried out on rice crops in Colombia's Meta department (in containers). The findings revealed that the introduction of glass silicon positively impacted rice production, even with reduced nitrogen fertilizer application. On average, rice crop yield increased by 21%-47% with the addition of glass silicon (compared to the absolute control with no fertilizers/additives). Furthermore, combining silicon with organic matter notably enhanced the presence of key nutrients (N, P, K) and certain minor nutrients (Fe, Cu, and B) in rice plants.

Through a grant in 2024, we have built on the previous trials and are conducting trials on tomato and potato crops. Commercial tomato varieties represent about 16.5% of Colombia’s horticultural area. Tomato crops are a nutrient-demanding plant; requiring a high availability of N, P, K, Ca, Mg, Cu, B, Zn. They also experience particularly high pest and disease issues in humid climates. The potato crop is a vital part of Colombia's Andean zone, covering approximately 110,000-135,000 hectares annually. The production is primarily for domestic consumption and fertilization constitutes 16.66% of production costs, the second-largest component after labor. The trials show promise thus far, with tomato harvest expected by May and potato harvest by July. We’ll have the final laboratory results for the soil and plant samples in August.

The crop type can affect the application method, optimal dosage rates, and frequency of silicon product application. With trials conducted through the FertLup project and those facilitated by Maxsil, we have established a solid foundation for guiding future crop trials in Colombia. Glass silicon showed clear benefits on its own, and we also found added advantages when combining it with compost, such as increased crop yield and potential disease tolerance. These results may influence product design in Colombia.

Maxsil manufacturing plant that produces glass silicon soil conditioner- Brisbane, Australia

At this crucial juncture, our project is positioned to benefit from additional support—financial, in-kind, and mentorship. We are nearing the conclusion of our current phase, which involves field trials and laboratory tests on potato crops, scheduled to be completed by July 2024. Subsequently, we aim to transition the project into the pilot stage, engaging paying customers.

Although we intend to proceed with trials on other key crops in Colombia to determine crop-specific dosage and product application recommendations, we are prepared to formalize the organization and register the product in Colombia. Following this, we can initiate imports of initial batches from Maxsil’s manufacturing plant. This step will enable us to generate revenue and acquire initial customers which will allow us to expand our team and develop the board. Support with importation and product distribution logistics would be valuable. With this traction, we intend to secure funding for constructing the first pilot recycling plant in Colombia to produce glass silicon.

Being part of a 9-month support program would greatly benefit both myself and the project. I am particularly keen on receiving leadership coaching and networking opportunities with fellow founders and organizations. Ideally, I hope to connect with individuals who share similar goals and would be interested in joining as founders to implement and run the project. Additionally, assistance with becoming investment-ready and measuring impact would be highly advantageous.

- Business Model (e.g. product-market fit, strategy & development)

- Financial (e.g. accounting practices, pitching to investors)

- Human Capital (e.g. sourcing talent, board development)

- Monitoring & Evaluation (e.g. collecting/using data, measuring impact)

- Product / Service Distribution (e.g. delivery, logistics, expanding client base)

Our solution seeks to support a low-carbon food system for both large and small-scale producers and supply chains. Our goal is to enhance crop yield, minimize food loss, and decrease GHG emissions attributed to fertilizer consumption. While our primary focus is on Colombia, the issue of GHG emissions in the crop nutrition sector and landfilled glass waste is a global concern.

One key innovation is Maxsil's patented process, which produces a high level of Plant Available Silicon (PAS). Instead of reinventing the wheel, we are leveraging an existing innovation and tailoring it to address the local markets and problems. This allows us to customize our solution to suit Colombia's unique soil conditions, agricultural practices and recycling system.

The product offers versatility, allowing for various characteristics such as granules or powder, and accommodating different methods of application based on crop type or cultivator preference. Glass silicon addresses soil acidity, enhances nutrient uptake and cycling, and prevents nutrient leaching, ultimately improving plant growth and soil health longer term. Increased crop yields with reduced NPK fertilizer and pesticide usage could enhance farmer profitability, thus illustrating that a more sustainable approach can also enhance economic viability. The crop nutrition sector also reaps long-term benefits from decreased GHG emissions resulting from the reduction in usage of imported nitrous oxide-producing fertilizers.

Given the benefits of incorporating compost with glass silicon applications, there could be opportunities to partner with compost facilities. This could boost demand for composting organic waste, maximizing resource utilization (and diverting methane-emitting waste from landfills) while promoting sustainable agricultural practices through the use of "waste fertilizers/nutrients”.

Moreover, our solution complements the glass recycling system by diverting waste that cannot be converted into cullet for new containers away from landfills. Additionally, it extends geographic coverage to areas lacking recycling infrastructure. By purchasing glass waste directly from local collectors, we can ensure they receive fair and consistent revenue.

Transitioning to a circular economy boosts economic growth and resilience for municipalities and communities; however, as there is no silver bullet solution, complementary approaches that consider impacts across the entire value chain are required. Regenerative food systems, centered around organic agriculture and local crop nutrition production will yield significant community benefits. Additionally, FertiLup showcases an innovative use for glass waste that will hopefully ignite other high-impact initiatives in the recycling and agriculture sector.

Evidence of community need & context:

Farmers/agribusinesses: We conducted interviews with agronomists, crop federations, and surveyed small-scale farmers to pinpoint challenges in the agricultural sector, especially regarding specific crops. Based on farmer feedback, 78% of respondents aim to enhance their crop yields.

Waste collectors: Collection centres have clients that consist of institutes, buildings, restaurants, hotels and businesses (in addition to residential pick up). Waste collectors generally have to collect all of the waste from clients but they often don’t have consistent sales channels for the glass waste, it’s not profitable. Some collection centres need to stockpile the glass waste regularly (see photo below).

Communities: During COP21, Colombia committed to reducing GHG emissions by 20% by 2030. Cultivated croplands and other agricultural activities contribute 14% of the total GHG emissions in Colombia. Low-income and disadvantaged communities are most impacted by climate change, soil and water pollution.

Activities:

Field trials on key crops in Colombia to test different dose rates of glass-silicon, NPK fertilizers, the impact of compost, and varying glass-silicon application frequencies. Soil samples are analyzed pre- and post-trials to assess nutrient impacts, while plant samples are evaluated for food quality and safety.

Once the plant capital has been raised, agreements with waste collectors and centro de acopios for the purchase of glass waste will be established.

Glass waste will undergo processing to produce glass silicon soil conditioner, accompanied by dose rate recommendations and guidance on reducing the use of other fertilizers and additives.

Immediate outputs:

Farmers have access to a sustainable source of high-plant available silicon for crop nutrition.

Glass waste, previously stockpiled, will be bought and transported to the plant several months before processing starts. A consistent market will procure glass waste from local collection centers.

Once the plant is operational there will be direct and indirect jobs created and partnership opportunities across the value chain.

Longer-term outcomes:

The utilization of glass silicon reduces the need for pesticides and NPK fertilizers, leading to cost savings for farmers, while also enhancing crop yields and soil health.

As the processing capacity of the plant increases, more glass can be purchased. Once the plant is integrated into the EPR scheme, further subsidies and investments may enhance the recycling system, improving waste collection and transportation for collectors.

Reduction in GHG emissions: The MRV calculation previously mentioned assessed a base scenario where nitrogen imported into Colombia was mixed with other elements, bagged, delivered, and applied to fields. The mitigation scenario, based on effective field trials, suggests that using glass silicon (30-100kg/ha dose rate depending on crop type) can conservatively reduce nitrogen use by 10%, thus lowering nitrous oxide emissions. In rice fields, methane emissions can be reduced by 6%. This scenario also considered CO2 emissions from glass silicon production and product transport. When projecting production over a span of 10 years, potential reductions in CO2 equivalent emissions amounted to 839,213 metric tons, with an average annual reduction of 83,921 metric tons of CO2 eq from glass silicon utilization.

Photo- Community in Cartagena, Colombia

Our impact goals as they align with targets/indicators from the UN Sustainable Development Goals:

2. Zero Hunger:

Target 2.3- Double the agricultural productivity and incomes of small-scale food producers.

Impact Goal: Increase crop yield (aim on average by 20%) and decrease crop nutrition/fertilizer costs (aim on average by 10%). This is assessed by analyzing the crops post-harvest and evaluating the enhancements resulting from the trials that had reduced nitrogen-based fertilizer application.

Target 2.4- Ensure sustainable food production systems and implement resilient agricultural practices that increase productivity and production.

Impact Goal: Measuring the kilograms of glass silicon product distributed in Colombia and the subsequent decrease in carbon footprint resulting from local manufacturing/production of glass silicon (tonnes).

9. Industry, Innovation, and Infrastructure- Innovation & research

Target 9.5- Enhance scientific research, upgrade the technological capabilities of industrial sectors in all countries, in particular developing countries.

Impact Goal: Innovative applications for recycled glass and field trials conducted on all major crops in Colombia, alongside continuous soil and plant laboratory testing. The objective is to provide comprehensive recommendations regarding dose rates, application methods, and product frequency for all key crops to minimize crop nutrition expenses in Colombia.

10. Reduced Inequalities/ 8. Decent work and economic growth- new revenue streams and employment opportunities

Target 8.2- Achieve higher levels of economic productivity through diversification, technological upgrading and innovation.

Impact Goal: Net value of glass silicon to the agricultural sector through crop yield/production, reduction in agricultural production costs, produce shelf life, farm gate prices, and resistance to pests and diseases.

Target 10.1- By 2030, progressively achieve and sustain income growth of the bottom 40 percent of the population at a rate higher than the national average.

Impact Goal: Increase in the volume of glass waste collected (in tonnes), recycled, and revenue generated for recicladores.

12. Responsible Consumption and Production

Target 12.5- By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse.

Impact Goal: Total glass waste (tonnes) diverted from landfill annually from recycling into glass silicon

13. Climate Action/15. Life on Land- GHG mitigation & soil quality

Target 13.3- Improve education, awareness-raising and human and institutional capacity on climate change mitigation, adaptation, impact reduction and early warning.

Impact Goal: In our customer survey, 22% of farmers want to prioritize climate change mitigation measures). Our goal is to increase this percentage by promoting education on the benefits of sustainable agricultural practices, including glass silicon, to mitigate GHG emissions.

Target 15.3- combat desertification, restore degraded land and soil, including land affected by desertification, drought and floods, and strive to achieve a land degradation-neutral world

Impact Goal: Improvements to soil conditions- acidity (pH) and achieving more optimal levels for major and minor nutrients (verified through laboratory tests)

17. Partnerships for the Goals- international collaborations

Target 17.3- Mobilize additional financial resources for developing countries from multiple sources

Impact Goal: Funds secured for the project through international grants, investments, and potential partnerships to advance and expand this solution.

There is a component of this solution that is rooted in ancestral technology/practices. Nature has demonstrated this concept of over millennia, exemplified by ecosystems such as the Serengeti and Amazon. Volcanic eruptions in these regions released ash, rich in molten silicates akin to MaxSil™ (glass silicon). These volcanic emissions were carried by trade winds, depositing ash over the Serengeti and Amazon. Subsequently, monsoon rains facilitated the conversion of ash to silicic acid, known as PAS, which contributes to robust plant growth. Silicon plays a pivotal role, both physically and chemically, in addressing soil acidity, enhancing the uptake and cycling of macro nutrients, and preventing nutrient leaching. Optimal soil conditions facilitated favorable agricultural conditions and biodiversity.

To produce the glass silicon products, a range of recycling and manufacturing technology will be utilized. At a high-level, this includes technology to clean, screen and resize the glass waste, and machinery to mill, classify and pelletize the recycled glass. There will also be equipment to store and bag the final product.

- A new application of an existing technology

- Ancestral Technology & Practices

- Biotechnology / Bioengineering

- Manufacturing Technology

- Materials Science

- Colombia

As the project is in the research and development phase, it is not presently generating revenue. Caitlin is contributing to the project on a part-time basis without compensation, while Didesagro (Alex and Jaime) serve as contractors for the field trials and deliver specialized education and logistical support tailored to the agricultural sector in Colombia.

Additionally, technicians and subcontractors are involved in supporting the execution of the field trials, including tasks such as irrigation and monitoring.

The Maxsil team (3 people) have continuously offered valuable strategic support for the project.

Five years ago, Lup, co-founded by Caitlin, embarked on finding sustainable end-uses for glass waste. As the solution evolved, its potential to address recycling challenges and crop nutrition emerged. Four years ago, Caitlin initiated collaboration with Maxsil, shaping the business case in Colombia. Despite pandemic-related delays, in 2023, Maxsil provided a sample of Maxsil™ product (glass silicon) for Colombian field trials. About three years ago, Didesagro began supporting the project, offering educational assistance on silicon utilization in Colombia's agricultural sector. Didesagro also designed the field trial protocol for FertiLup. In 2024, a grant from the Roddenberry Foundation continued field trials.

The project was built from the desire to ensure stable and fair work opportunities once the manufacturing plant is operational. As such, we conducted interviews and worked with other entities, NGOs, and waste collector associations etc. to ensure we were building financial projections and a business model that would be beneficial and inclusive for everyone. For example, for direct employees base salaries were projected to be at a minimum 55% higher than the Colombian minimum wage. We have also planned to create an option pool, so that all employees regardless of their position can access shares of stock in the future manufacturing plant.

Currently as the project is not generating revenue, much of the work is not compensated for those involved. However, grants and any funding is paid directly to Colombian contractors. There is always an emphasis on collaborating, receiving feedback and eventually hiring people who have both lived experience and local knowledge.

All communications are translated into both English and Spanish to ensure inclusivity for all participants. Additionally, specific terminology used by groups within their work environments is identified and incorporated.

We believe that waste should be managed close to where it is generated to reduce transportation costs and economically and socially benefit the local community. Rather than importing or exporting waste, we advocate for investment in local recycling systems backed by diverse and stable high-value markets.

Upon implementation of the solution, a recycling-based manufacturing facility will be established to produce glass silicon products for local farmers and agribusinesses. The pilot plant will be installed where it is closest to end-users and a consistent supply of glass waste to reduce transportation related costs and GHG emissions.

Glass waste will be purchased from recicladores for a fair per tonne price which will ensure additional and consistent revenue for them. Mixed-color glass can be converted into glass silicon, removing the necessity for recicladores to manually segregate glass by colour or store it until a sufficient volume is amassed to be economically feasible. This simplifies the process, enabling recyclers to boost revenue while minimizing labor requirements.

Target customers are farmers, farm cooperatives and agribusinesses that use fertilizers and soil conditioners (particularly high quantities of NPK fertilizers and/or slag silicates). Our objective is to secure sales of the glass silicon product through Federations and farming cooperatives, enabling them to promote the product to their members. This approach streamlines distribution by consolidating deliveries to specific locations, rather than to individual farms. We are focusing on producers of the following key crops: rice, corn, banana, plantain, coffee, cacao, cannabis/hemp (legal in Colombia), tomato, potatoes, blueberries, and palm oil. This selection is based on factors such as cultivation area in the region, dietary significance, existing challenges (including pests and diseases), and previous trial successes with silicon-based products.

Our solution has several B2B models:

End-users of the glass silicon product:

Direct sale of glass silicon (50Kg bags) to farmers and agribusinesses

Associations with agricultural federations for larger volume orders

2. Recycling system:

Subsidies for collection and processing costs from brands and producers for compliance with Extended Producer Responsibility (EPR) packaging laws

Additionally, there is a possibility of us serving as a public service provider for processing municipal and industrial waste, with the local government potentially being a customer (B2G).

Our business model generates positive impacts across various levels of the value chain. It maximizes economic benefits for the local community, minimizes environmental impacts by concentrating collection and distribution within a specific radius, and produces products that substitute less sustainable alternatives in the market for crop nutrition.

- Organizations (B2B)

Initially, Caitlin and her co-founder funded market research and feasibility studies through personal savings and consulting services. They later launched a successful crowdfunding campaign on IFundWomen, raising over $16,000 USD to design the field trial protocols, import the sample of glass silicon product and conduct field trials and laboratory tests for rice crops. Due to the progress and success of these trials, the project was awarded a grant through the Roddenberry Foundation (The Catalyst Fund) which allowed us to continue the field trials and laboratory tests for two additional crops. With promising outcomes, further grants are being pursued to expand trials to other key crops. We have sufficient product samples and potential partners (agricultural federations and agribusinesses) that we can collaborate with for these additional trials. Current focus prioritizes efficient resource allocation, with plans to register the glass silicon product and initiate imports into Colombia to kickstart revenue generation and cover operational expenses.

In the mid-term, our plan involves securing investment capital to establish the manufacturing plant in Colombia. While we garnered interest from investors in recent years, our early-stage status and lack of traction hindered securing seed funding. However, with tangible trial results and a proven concept in Colombia, we are now better positioned to reconnect with investors.

Once the plant becomes operational, it will sustain its activities by selling manufactured glass silicon soil conditioner/plant nutrient. We have devised several financial models for both equity investment and revenue sharing scenarios. These models account for the gradual expansion of shifts and processing capacity, as well as expenses associated with acquiring glass waste. A notable advantage of this end-product is its high value, enabling the plant to project a net income in its first year of operation. Moreover, no subsidies are necessary to cover transportation or recycling costs, as is often the case with other end-markets.

In addition, all projections were based on a conservative selling price that still places the glass silicon product 26-52% more cost effective compared to competitors in Colombia through a price/hectare comparison. The significantly increased plant-available silicon (PAS) in the MaxSil™ product (minimum of 36,000 ppm) results in reduced dosage requirements and higher farm gate prices, thereby enhancing returns.

There is also a possibility of securing service contracts with governments and/or brands and producers in the longer term. Colombia now has Extended Producer Responsibility (EPR) legislation, which requires producers to be financially responsible for the end of life of their packaging. By 2030, producers are responsible for recycling 30% of the packaging that they put in the market. The project received a letter of interest from a producer responsibility organization, comprising major beverage corporations, expressing their endorsement of our initiative and eventual integration into the EPR scheme upon operationalization. The letter also emphasizes the necessity for increased glass recycling infrastructure, particularly on the Caribbean Coast of Colombia.

Maxsil operates an industrial micronizing plant in Brisbane where production is ongoing, indicating the commercial viability of this product.